THE CHALLENGE

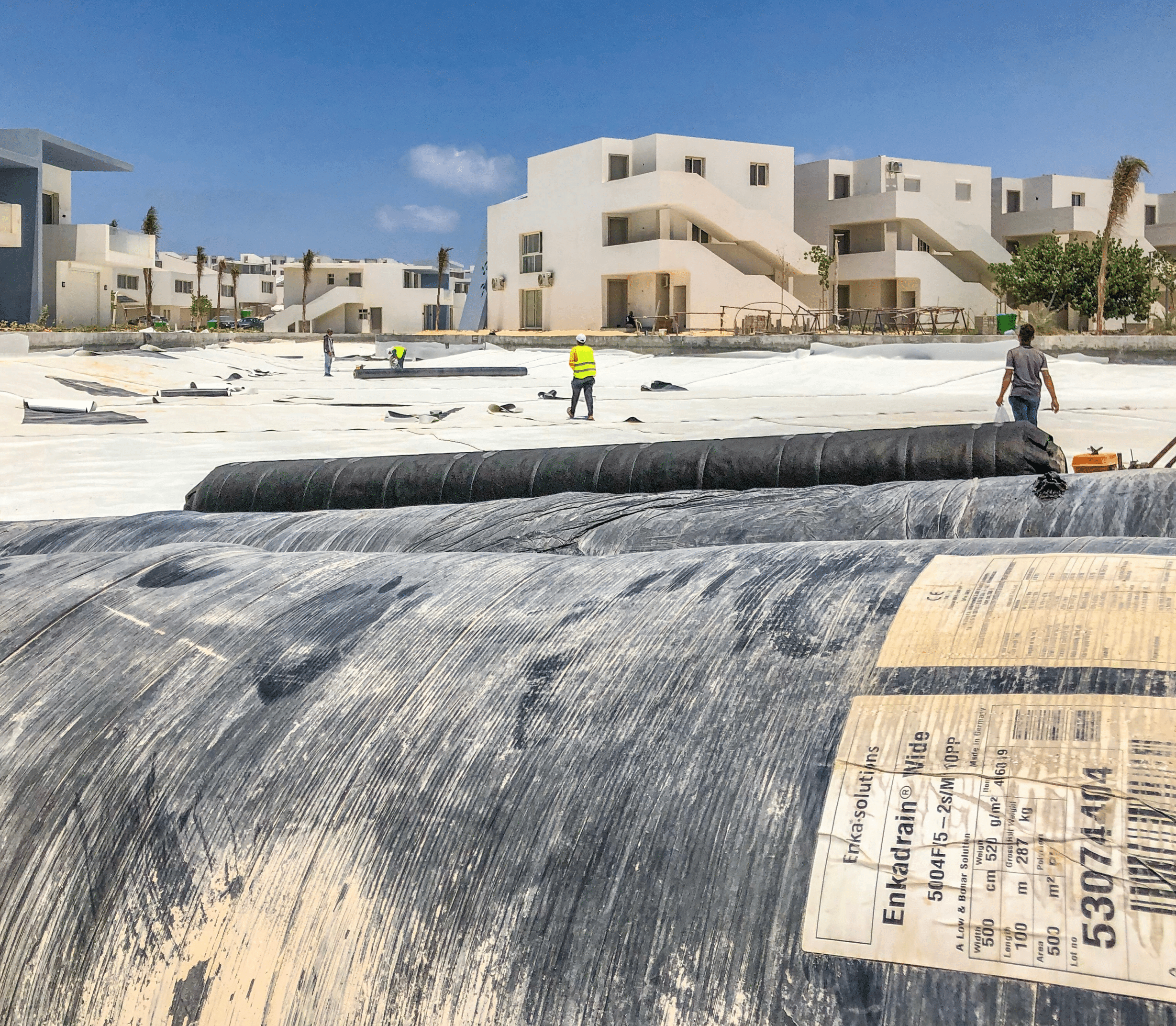

The Fouka Bay holiday resort is located in Egypt, near Alexandria and the Mediterranean Sea.

As part of the resort construction, a huge artificial lake, a so-called Public Access Lagoon has been built in the resort. This innovative technology makes building artificial beaches possible and accessible. These lagoons can be constructed virtually anywhere from public parks to shopping malls. They are environmentally friendly and provide the owner endless ways to monetize – weddings, concerts, restaurants, and water sports rentals. The demand for such projects has skyrocketed in past years and has the potential to become even more popular. In the future, Crystal Lagoons plans on developing a low-construction-cost dome over the lagoon so that even colder climates can enjoy Public Access Lagoons.

This lagoon is close to the real sea, which makes the construction conditions even more unique, but a perfectly working sealing system is required for the safety of guests and infrastructure. For us, the main challenge in the project was to find this waterproofing system. Reliable, quality solutions are the real key in these kind of projects. Building large water structures is expensive, so avoiding leakage is an important factor. The lagoon in constructed without vertical walls and a flexible bottom. This creates a special environment along with the high safety requirement.

THE ENKA SOLUTION

Originally, these lagoons use a multilayered sealing system, where two layers of waterproof HDPE membrane are separated with ~10 cm of sand. This way, the lower membrane still secures the system even if the upper layer is damaged.

Originally, these lagoons use a multilayered sealing system, where two layers of waterproof HDPE membrane are separated with ~10 cm of sand. This way, the lower membrane still secures the system even if the upper layer is damaged.

In traditional infrastructure construction, EnkaDrain products can be used for substituting sand drainage layers. However, using EnkaDrain in projects like artificial lakes and huge reservoirs is so new that it was considered an invention in Egypt.

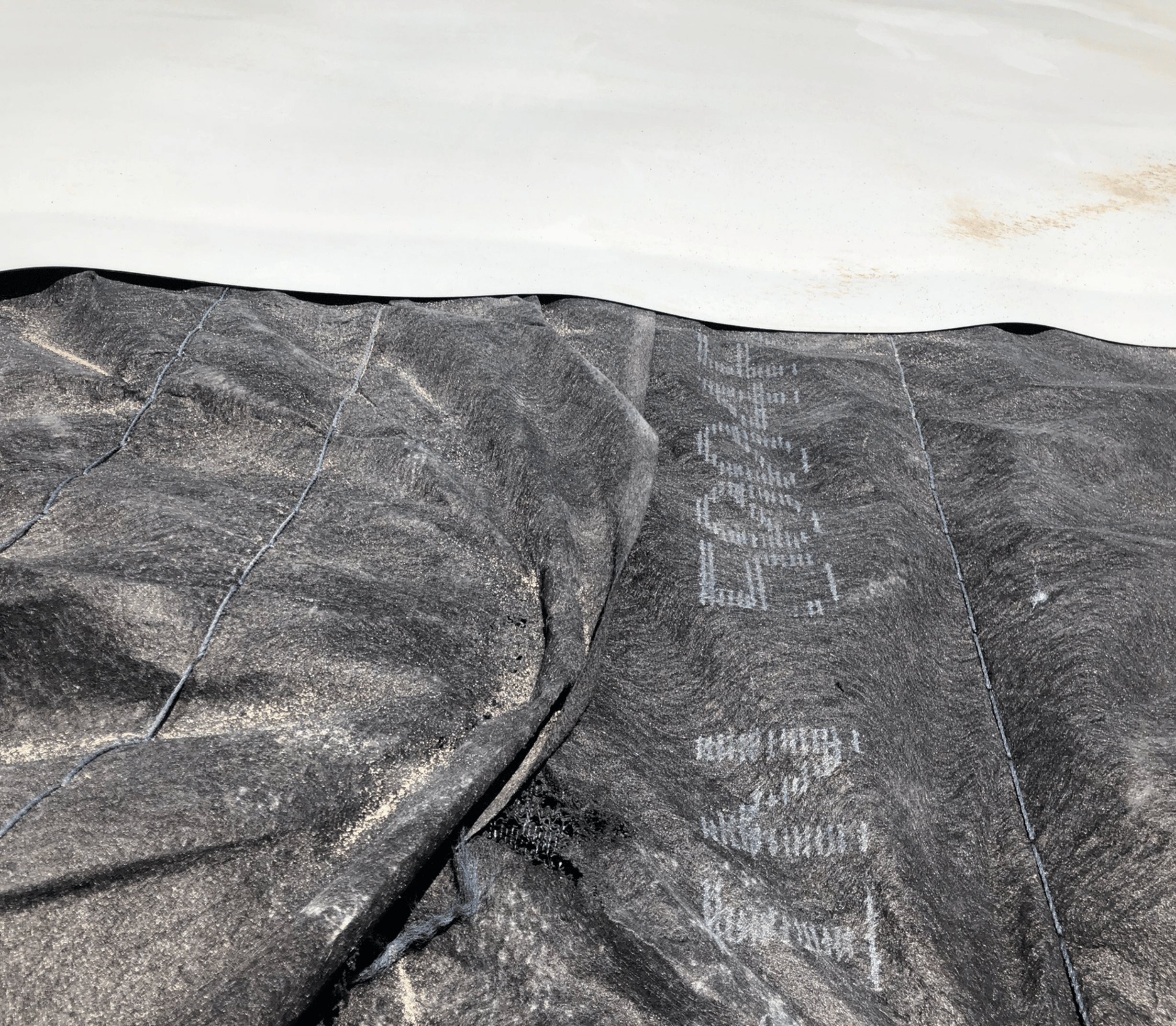

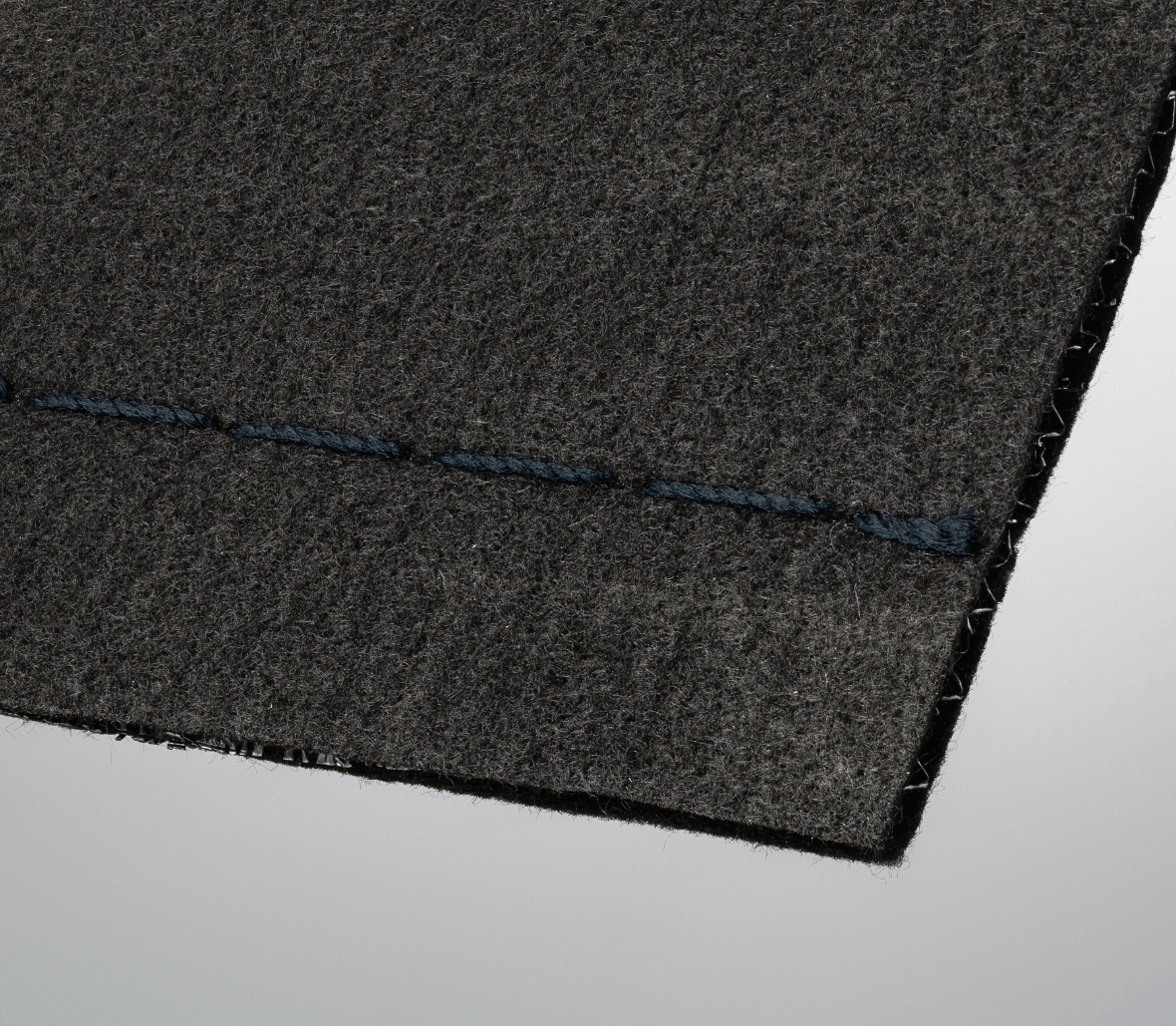

The final solution consists of two water impermeable layers separated with on layer of EnkaDrain 5004F/5-2s/M110PP. On the bottom, any leaking water is collected and drained by drainage pipes coated in nonwoven geotextile and covered in crushed gravel.

INSTALLATION BENEFITS & RESULTS

Using geosynthetics instead of traditional construction methods definitely provides a few advantages during and after construction. When chosen and used correctly, geosynthetics are a technically equivalent solution while being way more time and cost efficient. Discover the advantages for an environmentally conscious company like Crystal Lagoons, the installation benefits as well as results of the project in the case study pdf below.

- Americas

- Asia Pacific

- Europe, Middle East & Africa

- Case studies

- Product brochure

-

Artifical lagoon water sealing system at resort construction in EgyptCase study on EnkaDrain replacement for sand layers between waterproof HDPE membranesPDF 1mb

-

Drainage CompositesEnkaDrain | EnkaDrain Wide | EnkaDrain CKPDF 3MB