This is EnkaPack

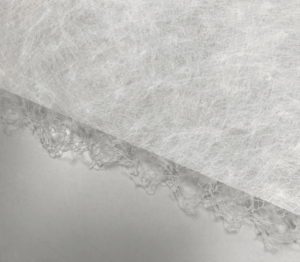

While a range of different variants of EnkaPack is available, they all have a number of characteristics in common: all EnkaPack filter media are made of entangled polypropylene monofilaments. These are fused together where they cross and thus form a pyramid-shaped three-dimensional matrix.

While a range of different variants of EnkaPack is available, they all have a number of characteristics in common: all EnkaPack filter media are made of entangled polypropylene monofilaments. These are fused together where they cross and thus form a pyramid-shaped three-dimensional matrix.

Up to 95 % percent of the filter medium is open and available for the flow of air and water. Thanks to a high surface area per volume ratio, the fibrous structure efficiently supports the growth of a biofilm: a powerful layer of microorganisms.

How EnkaPack is used in odor control and VOC treatment systems

In scrubber or trickling towers EnkaPack is installed inside the tank units into which contaminated gas streams are fed. In both cases it facilitates the uniform distribution of gas and water. And it provides an excellent habitat for the growth of microorganisms like sulfide-oxidizing bacteria. EnkaPack is compression resistant enough to effectively protect the biofilm from damage. This way, the medium ensures consistently high microbial biodegradation activity. Multiple layers can be stacked inside the tower without the risk of sagging and channeling. EnkaPack is inert to chemicals and organic solvents and reliably avoids clogging. What makes this film support stand apart from alternative synthetic packing media is its unique filament structure. EnkaPack provides up to 95 % of void space combined with a high specific surface area. Per cubic meter, microorganisms can grow on up to 650 square meters of filament surface. In bioscrubbers and biotrickling filters alike, EnkaPack so delivers a significant contribution to continuously high filter performance.

In addition to bioscrubbers and biotrickling filters, EnkaPack is also widely applied in humidifiers and demisters.

What makes EnkaPack the ideal filter medium?

Features:

- High surface area per volume ratio

- Up to 95 % of void space

- Uniform filament configuration

- Compression resistant, yet lightweight

- Resistant to chemicals and organic solvents

- The packing medium can be tailored to match specific needs

Benefits:

- High air permeability maximizes flow rates

- Ensures low-pressure drop to facilitate energy savings

- Promotes the consistent distribution of water and nutrients

- Ease of handling: Simple to cut and install

- Facilitates cost-efficient tank designs

- Long service life

- Allows glue-free connection to fabrics to prevent the nesting of birds

- Americas

- Asia Pacific

- Europe, Middle East & Africa

-

Synthetic Packing Media for Scrubbers and Biotrickling FiltersEnkaPackpdf 2mb