THE CHALLENGE

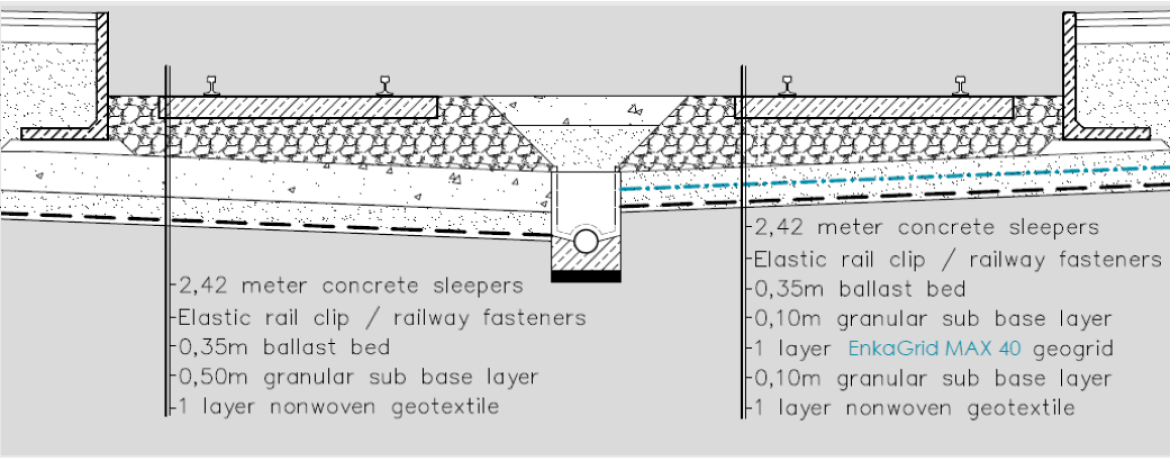

During the design of the Hungarian railway lines in 2014 the designers had to deal with cohesive soils with ineligible geotechnical parameters under the railway superstructures. A similar problem came up at the renewal of one of the busiest railway stations in North Hungary.

The subsoil under the sub base layer did not have enough bearing capacity to carry the heavy dynamic loads from the railway.

THE ENKA SOLUTION

• Installing one layer of EnkaGrid MAX 40 laser welded biaxial geogrid to reinforce the structure.

• Installing one layer of EnkaGrid MAX 40 laser welded biaxial geogrid to reinforce the structure.

EnkaGrid MAX 40 establishes an effective interlock which will stiffen the soil at the level of the grid.

It creates a composite material reaction which is better than pure tensile force alone.

INSTALLATION BENEFITS & RESULTS

Due to the polypropylene raw material of EnkaGrid MAX it can be used in every natural soil as well as recycled material with excellent durability and installation damage resistance.

The EnkaGrid MAX laser welded geogrid exhibits an optimal interaction with most of the granular soils, it can increase the service life of the whole construction, reduces the maintenance costs and the carbon footprint at the same time.

In this current application the EnkaGrid MAX 40 provided an immediate increase of the bearing capacity (the tensile strength is 16 kN/m at 2% strain) which enabled the construction of the ballast without increasing the thickness of the sub base layer. Furthermore, the use of these geosynthetics improves the load distribution and provides better settlement equalization in the long term.

- Americas

- Asia Pacific

- Europe, Middle East & Africa

- Installation Manual

- Product brochure

-

Composite GeogridsEnkaGrid MAX CPDF < 1mb

-

EnkaGrid MAX Base Reinforcement Installation ManualOfficial Installation guidelines from the manufacturerPDF 1mb

-

High Performance GeogridsEnkaGridPDF 3MB