THE CHALLENGE

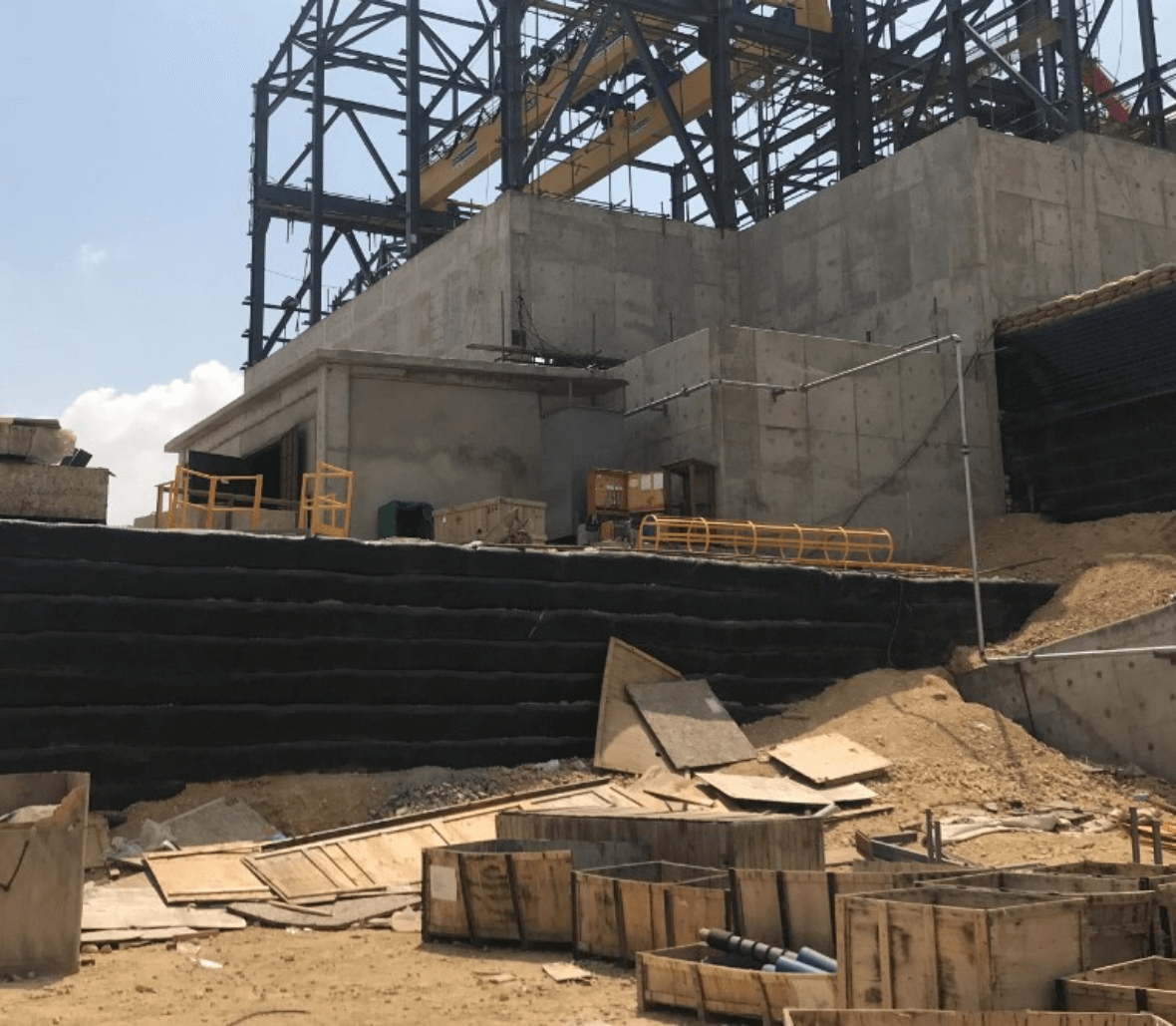

Space available for the project was extremely limited, making it necessary to build several retaining structures having heights of up to 17 m almost vertically. High vertical pressure on top of the structure from traffic loads in excess of 400 kPa very close to the edges had to be accommodated and peak ground acceleration (PGA) of 0.145 g had to be considered.

THE ENKA SOLUTION

Originally, the plan was to use concrete cantilever walls to provide this support but owing to the cost and complexity of these structures combined with the >10 m wall height, this original solution was discarded early in the project.

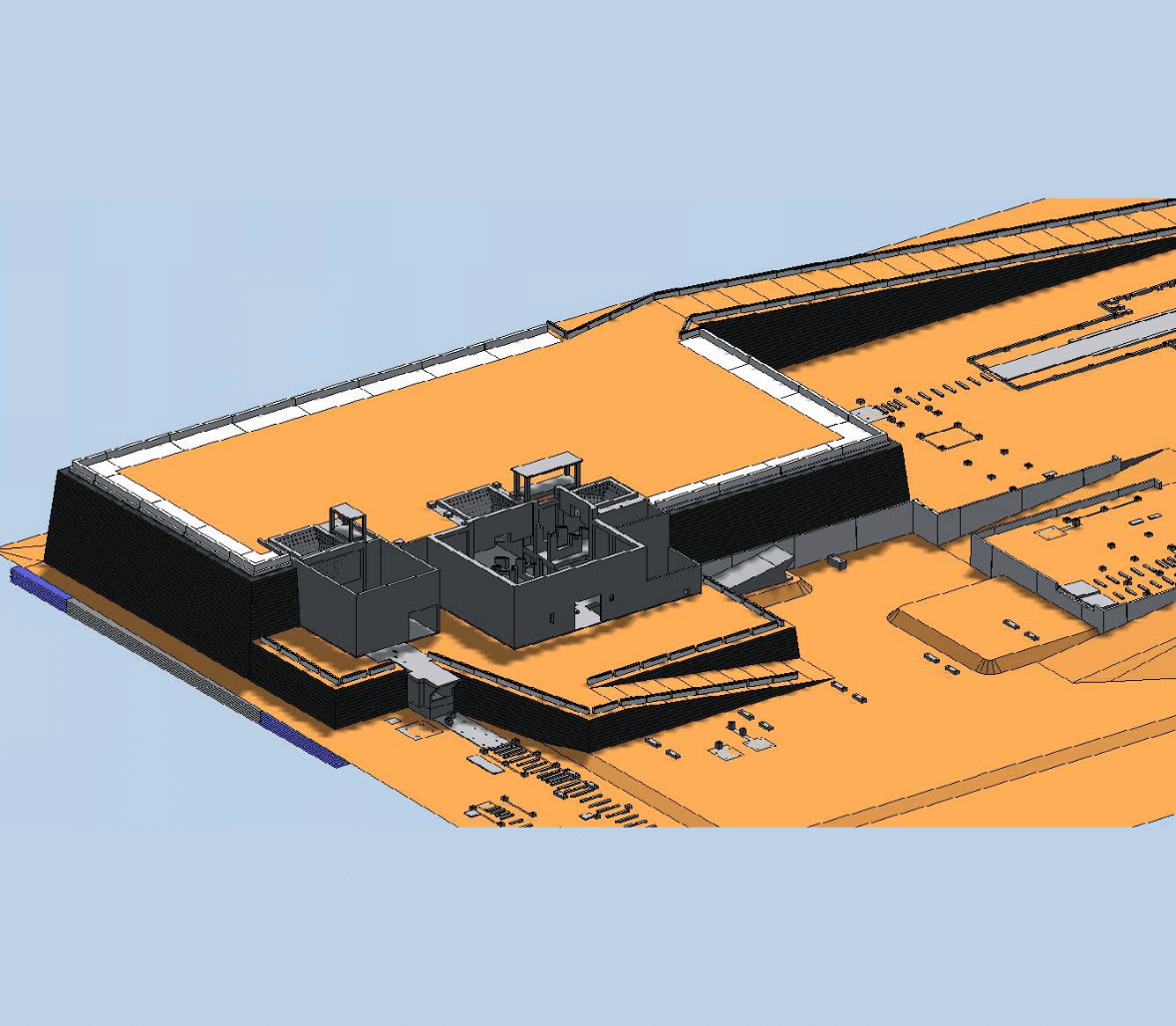

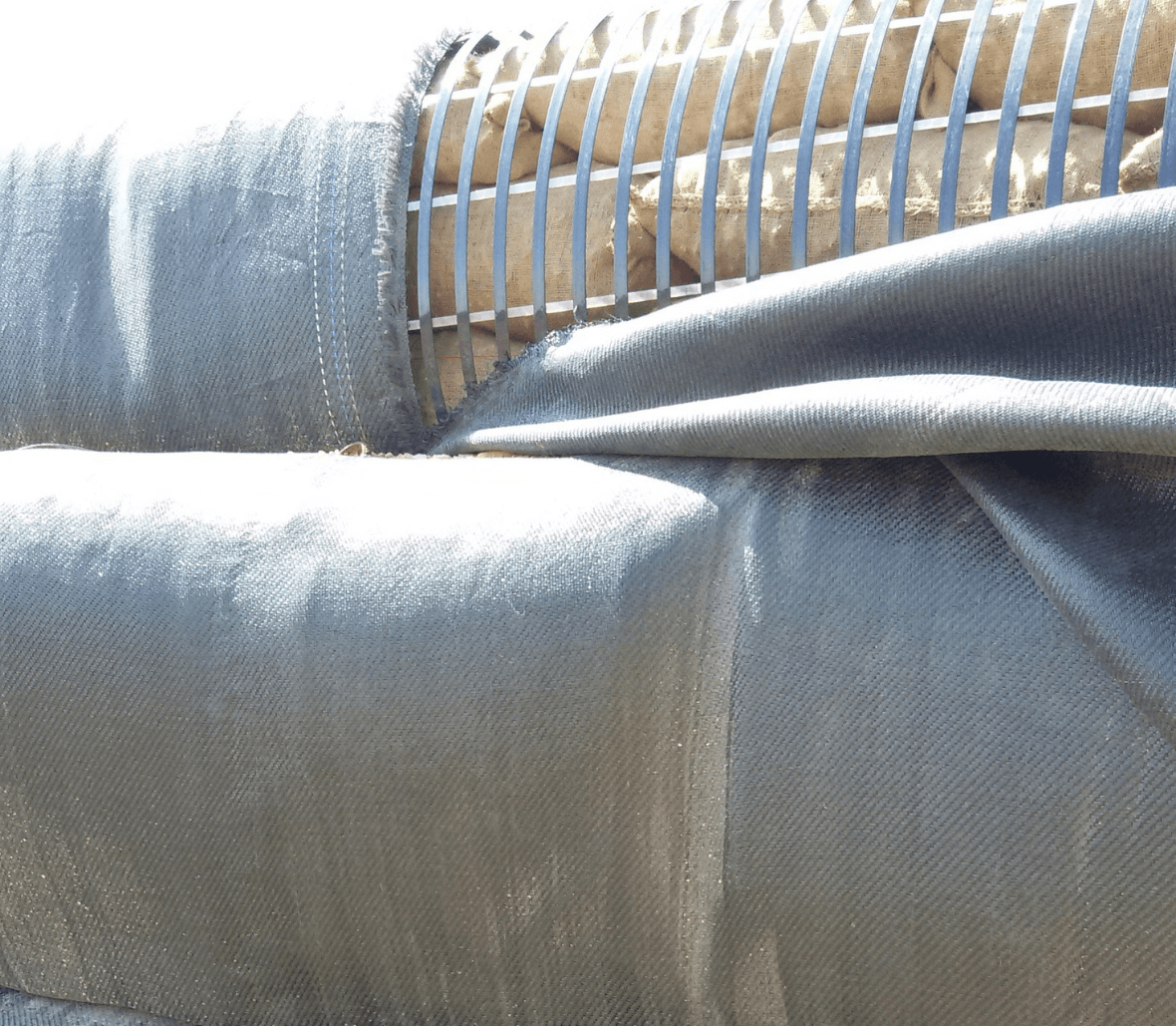

Ultimately, the option selected was the economically viable geogrid reinforced soil retaining wall system, using EnkaGrid PRO uniaxial geogrids with tensile strength varying from 60 kN/m up to 180 kN/m.

The surface area for the reinforced structure was divided into 15 geotechnical sections to facilitate a variety of calculations. Soil excavations and investigations on the site were performed and reported on, indicating that a layer of limestone bedrock was encountered at a more or less uniform depth, on average 2.0 m from the surface in all sections. Loose granular soil located above this layer was replaced and reinforced with EnkaGrid MAX 60 biaxial geogrid only under the toe of the structures.

The planning assignment prepared was based on EC 7 and related European geotechnical standards, including those pertaining to the internal and external stability of the structures.

INSTALLATION BENEFITS & RESULTS

Using Enka Solutions, the contractor was able to make maximum use of the available space to achieve a more economical construction when compared to other options.

The construction of the areas for the limestone crushers intended to supply the increased capacity of the expanded factory was successfully completed. Before the construction, the cement plant produced 1,500 tons of cement per day, whereas the total capacity of the extended plant, complete with crusher and new silos, was now increased to 7,700 tons.