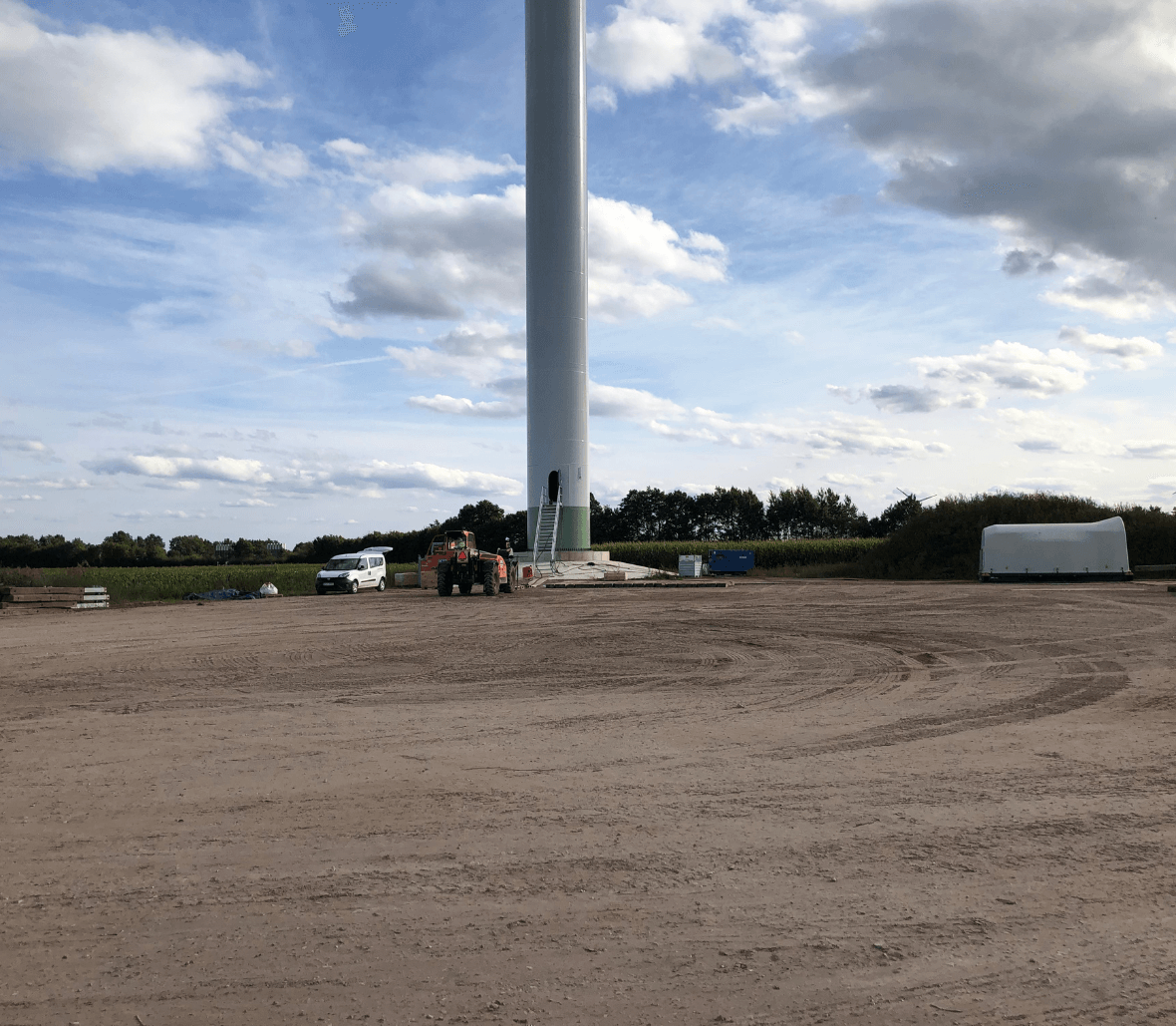

How are EnkaGrid geogrids used to reinforce working platforms?

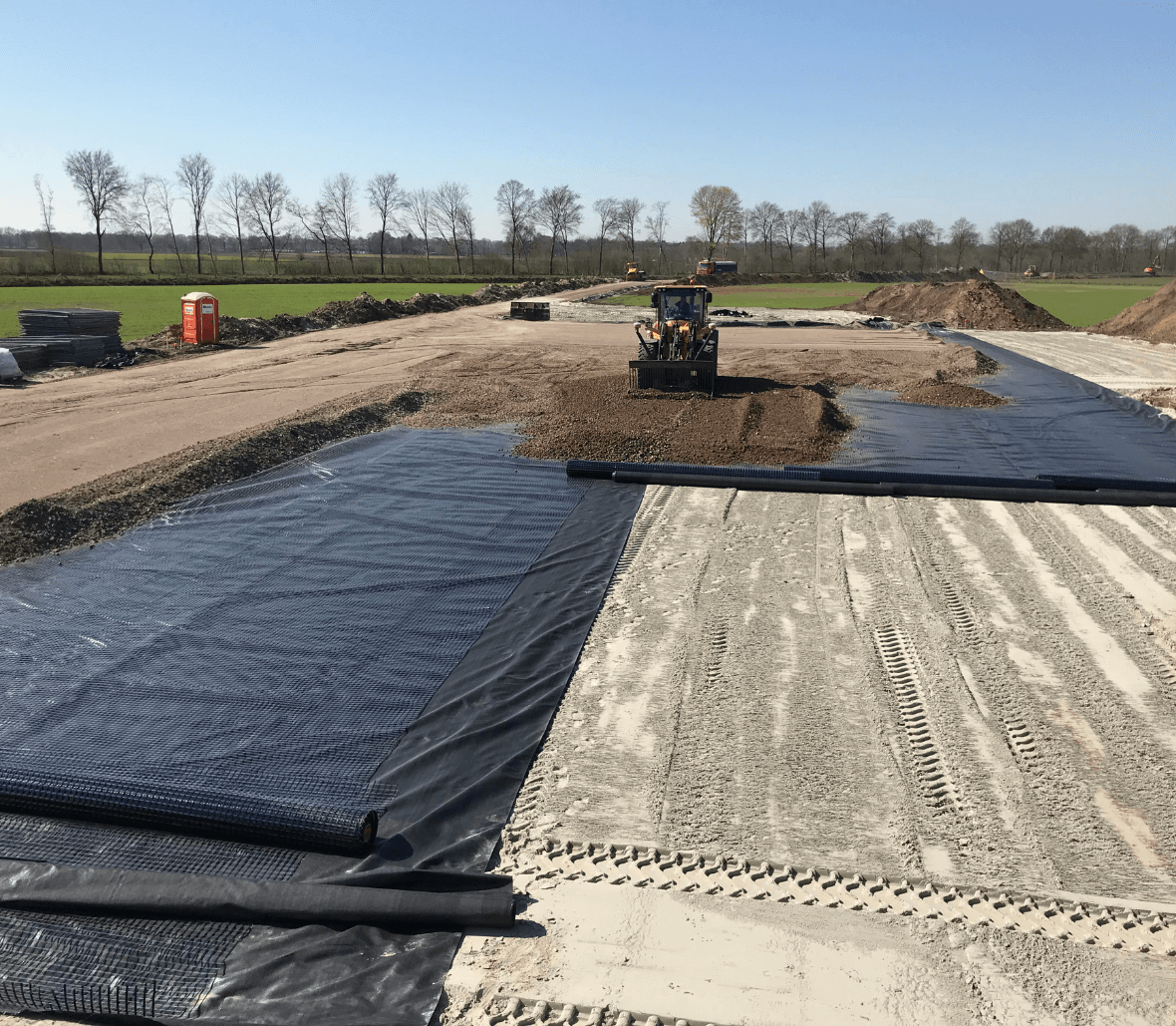

Traditional methods of improving the bearing capacity of weak soil involve large excavations to replace the soil with better material. Alternatively, rigid alternatives such as steel or concrete piles are used to transfer high surface loads to lower soil layers. Both methods are associated with a high material demand, long lead times, and substantial CO2 emissions. EnkaGrid MAX, EnkaGrid MAX C and EnkaGrid TRC geogrids provide an effective and cost-efficient alternative to create a strong sub-base. When used to reinforce working platforms, they allow a reduction of the thickness of the sub-base and eliminate or reduce the need for soil replacement.

EnkaGrid MAX and EnkaGrid MAX C provide the strength needed to reduce shear stresses in the sub-base. It substantially enhances its load-bearing capacity and stabilizes the platform for a long service life. The geogrid has an optimum interaction with almost all granular soil types. This makes it the ideal reinforcement for the most diverse challenges.

Thanks to their high modulus and low elongation, EnkaGrid TRC geogrids mobilize forces while avoiding deformation of the subbase. Meanwhile, the nonwovens perform as a separator and filter. This prevents the mixing of the fill and subsoil. And the nonwovens avert pumping of fines from the subsoil into the base. This is an important advantage when it comes to designing working platforms cost-efficiently.

Available geogrids

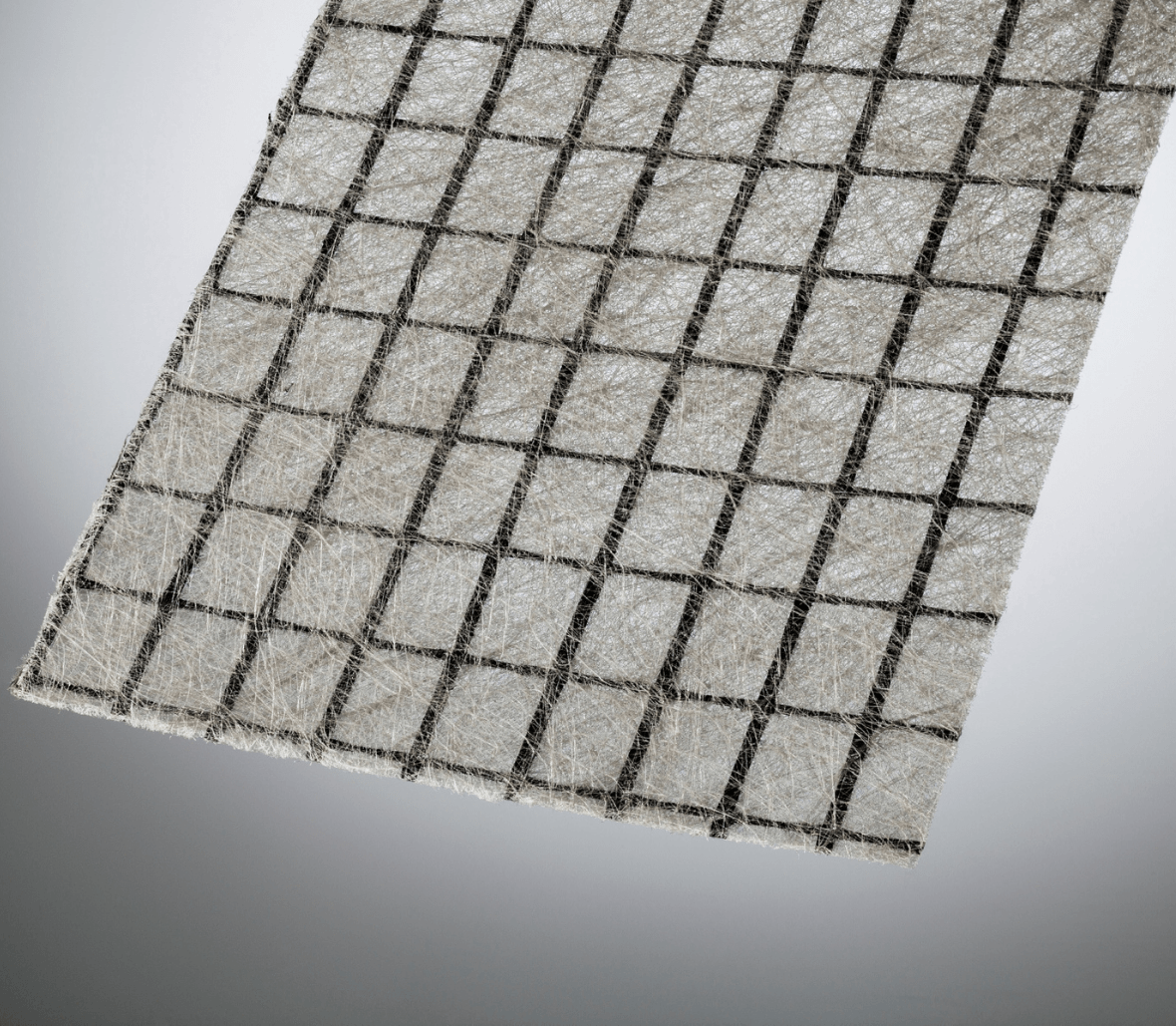

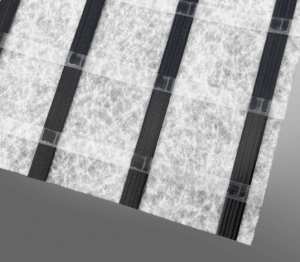

This is EnkaGrid MAX C

EnkaGrid MAX C is a high-performance and cost-effective biaxial geogrid composite used worldwide in civil engineering projects for reinforcing granular base courses and separating different soil layers.

EnkaGrid MAX C is a high-performance and cost-effective biaxial geogrid composite used worldwide in civil engineering projects for reinforcing granular base courses and separating different soil layers.

It is designed for achieving maximum bearing capacity and shear resistance. The incorporated fleece ensures long-term filtration stability and provides ideal separation of different soils ranging from clay to coarse granular fill.

EnkaGrid MAX C is available in different strengths, aperture size and tensile strength with different filter fleeces for long-term efficient soil reinforcement.

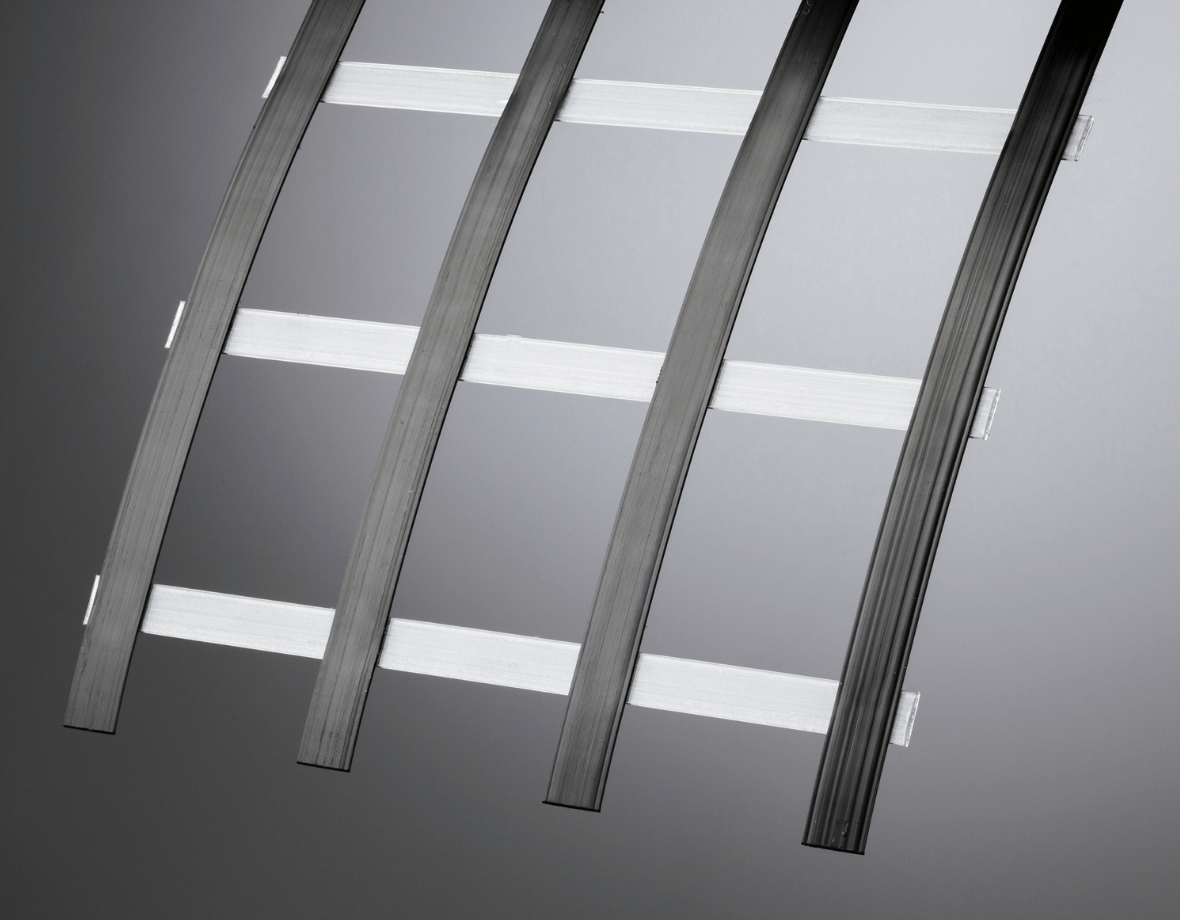

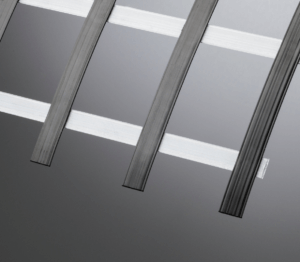

This is EnkaGrid MAX

EnkaGrid MAX is a rigid, laser-welded biaxial geogrid made of extruded polypropylene or polyester strips of equal tensile strength in both longitudinal and transverse directions.

EnkaGrid MAX is a rigid, laser-welded biaxial geogrid made of extruded polypropylene or polyester strips of equal tensile strength in both longitudinal and transverse directions.

Thanks to a patented computer-controlled manufacturing process, the geogrid exhibits consistent stress-strain behavior over the entire area.

EnkaGrid MAX is available in a number of different strengths. For optimal speed of installation the geogrid is delivered in widths up to five meters.

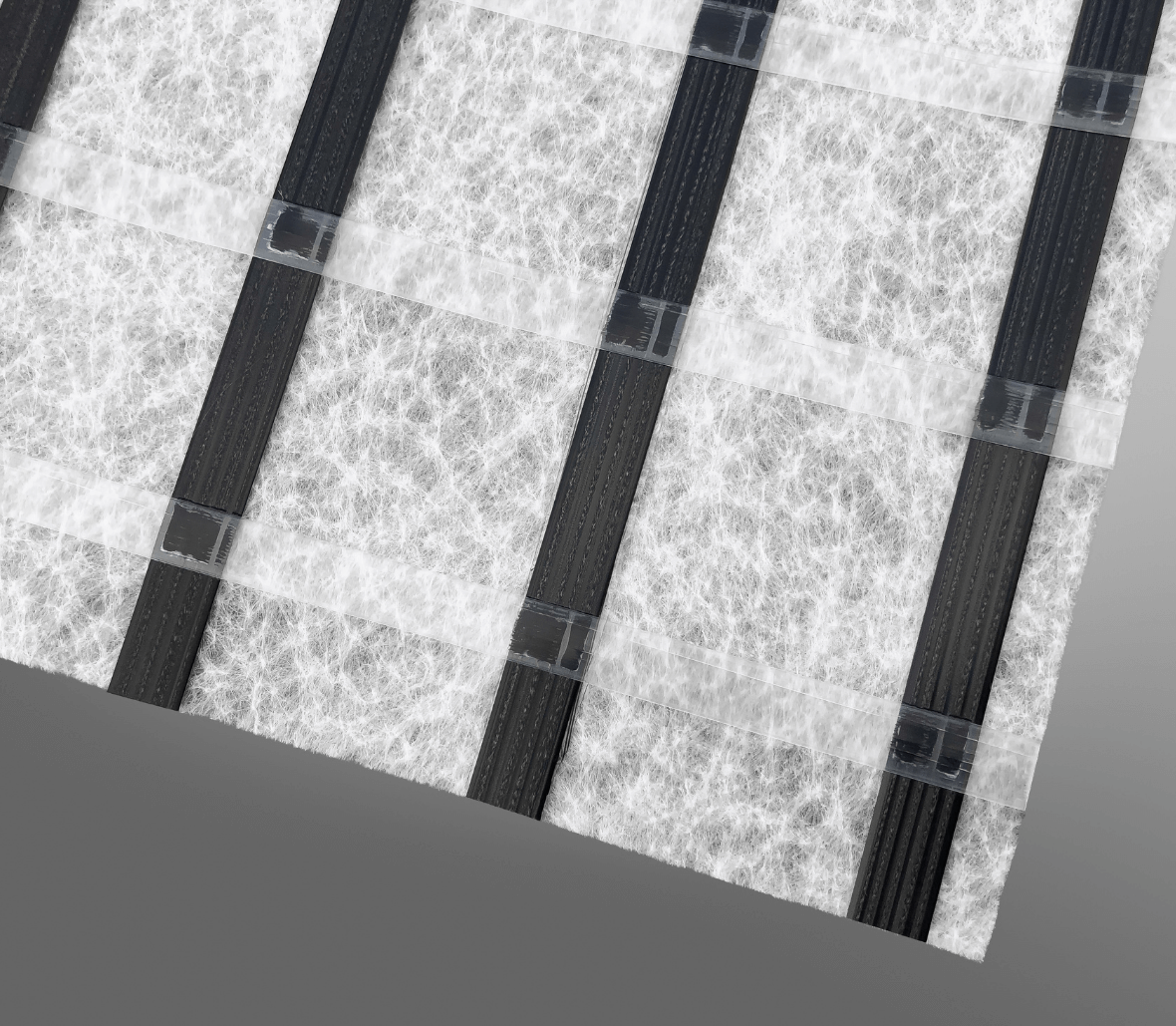

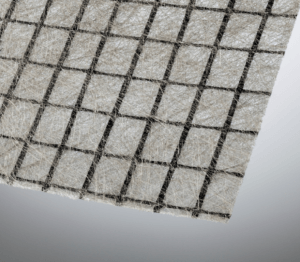

This is EnkaGrid TRC

EnkaGrid TRC is a multifunctional geogrid composite. It exhibits equal tensile strength in both longitudinal and transverse directions.

The geogrid consists of a PVA-coated aramid mesh, which provides an exceptional strength to weight ratio.

This mesh is embedded in thermally bonded nonwovens. Thanks to this unique design EnkaGrid TRC fulfils the functions of reinforcement, separation and filtration in one easy-to-install product.

What makes EnkaGrid MAX, EnkaGrid MAX C and Enkagrid TRC geogrids the optimal reinforcement for working platforms?

Features:

- Creates an excellent soil-grid interaction for all types of soil (Enkagrid MAX)

- High radial stiffness (EnkaGrid MAX)

- Multifunctional geogrid (EnkaGrid TRC)

- High modulus, low strain – mean value 3.5% (EnkaGrid TRC)

- Consistent stress-strain performance

- Wide product range to suit specific project requirements

- Excellent mechanical long-term durability

- Superior resistance to mechanical damage

- Extensive design support and technical documentation available

Benefits:

- Reliable and proven reinforcement solutions

- Effective reduction of differential settlement

- Opportunity to realize cost-efficient road and rail designs

- Ease of handling on site

- Fast installation

- CO2 emission savings

- Americas

- Asia Pacific

- Europe, Middle East & Africa

- Installation Manual

- Product brochure

-

Composite GeogridsEnkaGrid MAX CPDF < 1mb

-

EnkaGrid MAX C Installation ManualOfficial Installation guidelines from the manufacturerPDF 1mb

-

EnkaGrid MAX Base Reinforcement Installation ManualOfficial Installation guidelines from the manufacturerPDF 1mb

-

EnkaGrid TRC Installation ManualOfficial Installation guidelines from the manufacturerPDF 1mb

-

High Performance GeogridsEnkaGridPDF 3MB