This is EnkaChannel

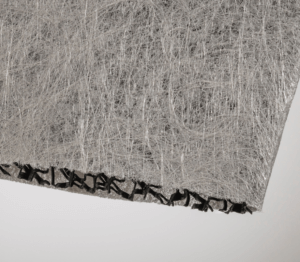

EnkaChannel consists of a three-dimensional spacer matting wrapped in a thermally bonded nonwoven sleeve. The spacer is produced from polymeric monofilaments. These are pre-formed into a compression-resistant, yet flexible zig-zag configuration.

EnkaChannel consists of a three-dimensional spacer matting wrapped in a thermally bonded nonwoven sleeve. The spacer is produced from polymeric monofilaments. These are pre-formed into a compression-resistant, yet flexible zig-zag configuration.

To accommodate different process settings and composite-part designs, EnkaChannel is available in two different widths. Both product variants come on 100 meter long rolls. EnkaChannel is easy to cut to size and fix in any mold.

How EnkaChannel is used in vacuum infusion

No matter how different the industries in which vacuum infusion is applied to produce composite parts, the basic principle is always the same: Rather than applying resin by hand, infusion uses vacuum pressure to drive resin into a laminate. A vacuum pump pulls the resin into the system by way of vacuum lines and a flow medium in the mold. The feed lines are connected to EnkaChannel, which acts as a feeder facilitating fast and regular resin transport into the composite part. Thanks to its high constant flow rates exceeding that of tubes and hoses, the product makes processing more efficient and helps reduce infusion time. At the same time, EnkaChannel’s unique configuration enables resin flow in x, y and z direction. And with EnkaChannel the imprints known from spiral wraps are also a thing of the past.

EnkaChannel is often applied in combination with an EnkaFusion resin transfer media.

What makes EnkaChannel the ideal resin feeder?

Features:

- 50 mm or 100 mm wide

- 4 mm thick

- Open structure with up to 95 % of void space

- High compression resistance

- Flexible

- Chemically inert

Benefits:

- Facilitates fast and constant resin flow to minimize infusion time

- Simple to fix in the mold

- Leaves no imprints on surfaces

- Maximizes efficiency of resin use

- Compatible with all types of resin

- Easy to cut

- Americas

- Asia Pacific

- Europe, Middle East & Africa

-

Consumables for resin infusion processesENKA®CHANNEL & ENKA®SPACERpdf 1MB

-

Spacer for reaction injection moulding processesENKA®SPACERpdf 2MB

-

Flow media and spacers for vacuum infusion and structural injection moulding[NEW] Solutions Overviewpdf 3mb