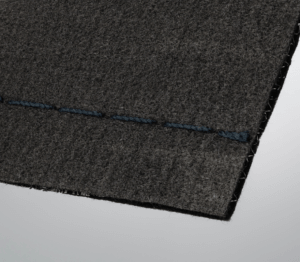

This is EnkaDrain Wide

Enkadrain Wide drainage mats are multifunctional, light and flexible geocomposites. Their drainage core is composed of synthetic monofilaments, which are thermally pre-formed into a V-shape configuration. This makes the product optimally pressure resistant. The drainage mat is produced with a width of five meters. For landfill applications, EnkaDrain Wide is covered with mechanically bonded nonwoven filters on one or both faces. However, the product portfolio also includes EnkaDrain Wide variants with thermally bonded nonwoven filters. The nonwovens are stitched to the drainage core. The stitching lines are parallel to the machine direction. Each of the nonwoven filters overlaps one edge of the core by 100 millimeters. This ensures that the joint is fully covered when rolls of EnkaDrain Wide are laid adjacent to another.

Enkadrain Wide drainage mats are multifunctional, light and flexible geocomposites. Their drainage core is composed of synthetic monofilaments, which are thermally pre-formed into a V-shape configuration. This makes the product optimally pressure resistant. The drainage mat is produced with a width of five meters. For landfill applications, EnkaDrain Wide is covered with mechanically bonded nonwoven filters on one or both faces. However, the product portfolio also includes EnkaDrain Wide variants with thermally bonded nonwoven filters. The nonwovens are stitched to the drainage core. The stitching lines are parallel to the machine direction. Each of the nonwoven filters overlaps one edge of the core by 100 millimeters. This ensures that the joint is fully covered when rolls of EnkaDrain Wide are laid adjacent to another.

How EnkaDrain Wide is used for gas venting in landfills

Proper gas-relief performance is a major design element of every landfill. It requires the proper number and spacing of collection wells and trenches, adequate sizes and depths of well boreholes, as well as proper packing and sealing around the well screens. Gas-venting systems designed with EnkaDrain Wide remove gases from landfill caps by creating a void below the impermeable geosynthetic barrier. Enkadrain Wide collects the landfill gases and discharges these to conductive perforated drainpipes installed in gravel trenches. The gases are safely vented from the landfill via outlet points. The highest discharge capacity of EnkaDrain Wide is in machine direction. Ideally, the drainage mat should therefore be installed with the machine direction parallel to the expected flow direction. Thanks to the unique filament structure, passage of gas in the cross-machine direction of the composite is ensured. EnkaDrain Wide comes on large rolls with a width of five meters and a length of 100 meters. This supports speedy installation, an advantage for landfill contractors and project owners alike.

In addition to its use as venting layer in landfill capping layers, EnkaDrain Wide is also used as a drainage layer for rainwater as well as for side and base drainage .

What makes EnkaDrain Wide the ideal gas venting solution?

Features:

- Highly pressure-resistant drainage composite

- Successfully used for over 40 years

- Long-term performance proven by landfill excavations

and laboratory tests - Large roll size (5 m x 100 m)

Benefits:

- Superior discharge capacity under high loads

- High flow rates even at low gradients

- Protects geomembranes from damage

- Facilitates speedy installation

- Cost-efficient solution

- Americas

- Asia Pacific

- Europe, Middle East & Africa

- Installation Manual

- Product brochure

- Solutions brochure

-

LandfillsSolutions OverviewPDF 5mb

-

EnkaDrainWide Landfills Installation manualOfficial Installation guidelines from the manufacturerPDF 4mb

-

Drainage CompositesEnkaDrain | EnkaDrain Wide | EnkaDrain CKPDF 3MB