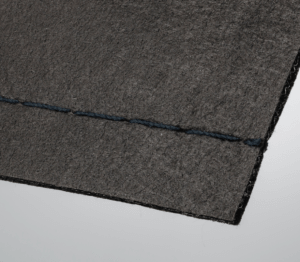

This is EnkaBreak

EnkaBreak is a range of multifunctional geocomposites. Their core is made of durable polymeric three-dimensional monofilaments wet-spun into a highly pressure resistant, yet open V-shape configuration. The core is equipped with separation/filter geotextile fabrics on both sides. To comply with the requirements of different project parameters, these fabrics can be thermally or mechanically bonded. Available with a thickness of four or six millimeters, EnkaBreak is supplied in five meter-wide rolls. This facilitates fast installation. In addition to its function as capillary-break layer, EnkaBreak also acts as a drainage layer which provides a high discharge capacity and allows rainwater to escape in all directions.

How EnkaBreak keeps structures safe and dry

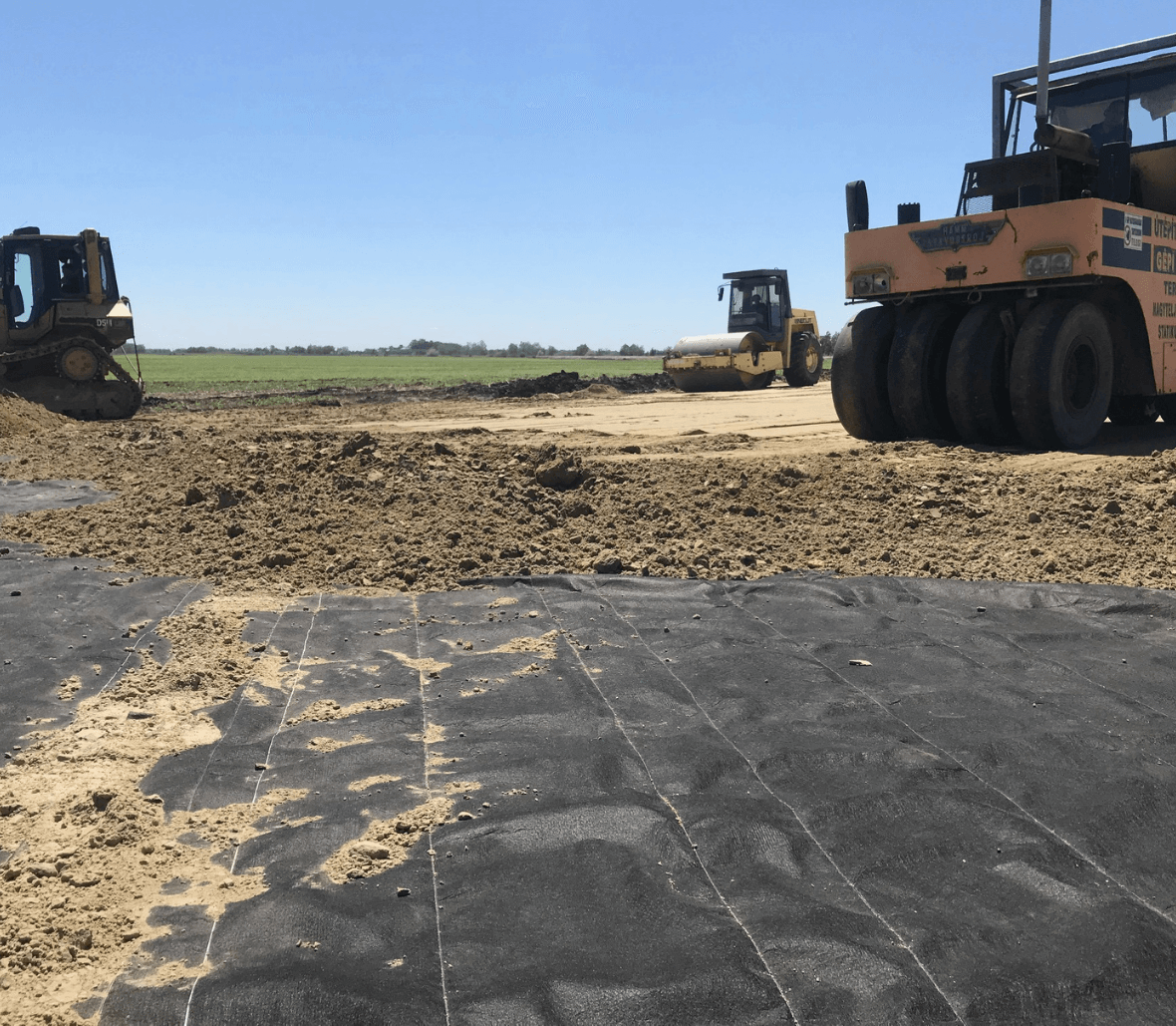

A proven alternative for granular capillary break layers, EnkaBreak effectively mitigates the impact of high or differential groundwater conditions. The geocomposite is installed above the highest level of the water table. Here it creates a horizontal void space, preventing moisture from rising from a saturated subsoil to the built structure. This ensures that foundation layers retain their design properties. The unique design of EnkaBreak safeguards the product’s excellent long-term performance: the combination of a pressure-resistant core with geotextile filter fabrics complying with specific stiffness requirements ensures that the void space remains open over the entire lifespan of the structure. Filter intrusion, a phenomenon where extensible geotextiles are forced into the core of certain geocomposites, is reliably avoided even under the highest loads.

Capillary breakage solution using EnkaBreak, in case of high groundwater level coupled with backfill height > 2m

Capillary breakage solution using EnkaBreak, in the case of polder wetlands associated with low embankments

In addition to interrupting capillary rise in soil, EnkaBreak acts as a drainage layer. Its V-shape monofilament core exhibits its highest discharge capacity in channel direction. For maximum performance therefore rolls are laid parallel to any slopes.

Where EnkaBreak is used to replace granular capillary-break layers, substantial savings can be realized with regard to the amount of excavation and quarry material required. This is a win-situation for both the environment and for cost savings. Construction can be completed in a shorter time, and maintenance intervals be extended.

For use in arid regions where saline groundwater levels are relatively high and pavements, building foundations or vegetation need protection against the influences of salt, a special product variant is available: marketed as EnkaSaltBarrier, this capillary break layer includes a hydrophobic geotextile fabric.

What makes EnkaBreak a cost-efficient and environmental friendly capillary break layer?

Features:

- Multifunctional: Acts as capillary-break layer and drainage mat

- High discharge capacity

- Excellent pressure resistance

- Product design tailored for long-term high performance under high loads

- Delivered on five meter-wide rolls

- Extensively tested and performance-proven in growing number of projects

Benefits:

- Replaces granular capillary break layers

- Minimizes construction time

- Facilitates cost-efficient project designs

- Significantly reduces truck movements and saves CO2 emissions

- Enhances the life expectancy of the finished structure

- Reduces required maintenance and repair

Downloads

- Americas

- Asia Pacific

- Europe, Middle East & Africa

-

EnkaDrain Salt Barrier Installation ManualOfficial Installation guidelines from the manufacturerPDF 1mb

-

EnkaBreak Capillary Break Layer Installation ManualOfficial Installation guidelines from the manufacturerPDF 1mb

EnkaBreak sales offices (Contact your nearest office)

Other geotechnical solutions

Discover other solutions for civil engineering projects.